Description:

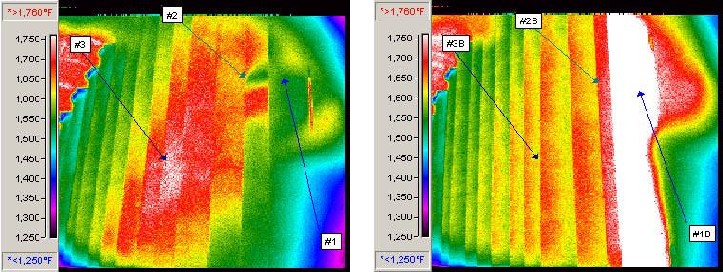

The above thermograms are of Steam Reformer Tubes before (Left) and after (Right) repairs.

A Steam Reformers job is to make Hydrogen Gas. In simple terms, this is done by passing water vapour and natural gas inside catalysts filled tubes and heating them up by means of gas burners. So you can basically say that inside each tube is Hydrogen Gas.

Left Thermogram:

Here we see three arrowed sections:

- Arrow #1 indicates a leaking tube. (Nothing is seen on this tube because the actual leak is out of the direct view).

- Arrow #2 indicates a "Cold" Band on the tube adjacent to the leak. (This Cold Band is the actual hydrogen gas leak hitting the tube and cooling it at that location).

- Arrow #3 indicates the "After burn" of the hydrogen gas as it flows deeper into the reformer and is ignited by the burners.

Right Thermogram:

Here we see the same tube section after repairs:

- Arrow #1B indicates the leaking tube being "Crimped". (A Crimped tube shows up hotter because it no longer has gas flowing through it to cool it down).

- Arrow #2B indicates that the "Cold" band is no longer present.

- Arrow #3B indicates that there is no more signs of "After Burn".

Conclusion:

Problem was identified and repaired online thus preventing a catastrophic failure and downtime.

Case Study Submitted By:

Sonny James

Level III Certified Infrared Thermographer

Thermal Diagnostics Limited

Tel/Fax: (868)-657-6572